mahaveerrubber@gmail.com - GST NO. : 09AGBPJ9854C1ZB

- Send Email

1.00 - 10,000.00 / piece( + 18% GST applicable)

| Business Type | Manufacturer, Exporter, Supplier |

| Brand Name | MRI- LamiG8 |

| Material | Rubber |

| Handle Material | MS |

| Click to view more | |

Product Details

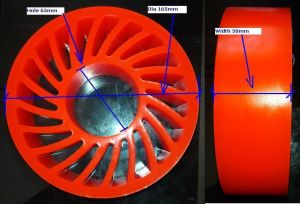

Wheel Material

MS

Shape

Round

Color

BLUE

Application

Lamination Use

Length

500-1500

Port

UTTAR PRADESH

Delivery Time

3-5 days

Packaging Details

BOX PACKING

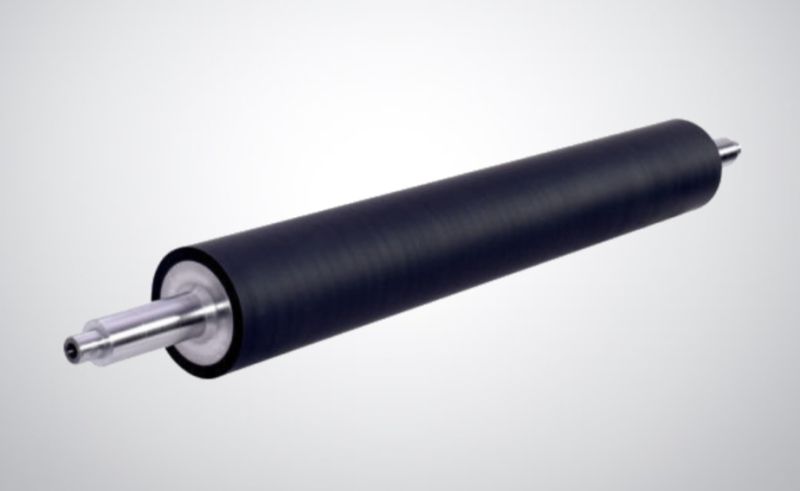

A glue lamination rubber roller is a specialized roller in a laminating machine that applies heat and pressure to fuse a protective film or laminate to a substrate, ensuring smooth, uniform, and bubble-free adhesion. Made from heat-resistant rubber, such as silicone or EPDM, these rollers come in various sizes and hardness levels to suit different materials and machine types. Their primary functions are uniform pressure application, even heat distribution, and durable performance under high temperatures and mechanical stress.

Key Functions & Characteristics

-

Pressure Application:The roller applies consistent and even pressure, which is crucial for preventing bubbles, wrinkles, and ensuring the laminate film adheres properly to the substrate.

-

Heat Distribution:In heated lamination processes, the rubber roller helps distribute heat evenly, allowing for optimal bonding between the laminate and the material.

-

Material Resistance:Made from high-quality, heat-resistant materials like silicone or EPDM rubber, these rollers can withstand the high temperatures and pressures of the lamination process without degrading or wearing out.

-

Customization:Rollers can be customized in terms of size, surface texture, and hardness to meet the specific requirements of different lamination machines and materials.

-

Durability:Designed for heavy use and long-term operation, rubber rollers are built to be wear-resistant, providing a durable and long-lasting solution for lamination.

Types and Applications