mahaveerrubber@gmail.com - GST NO. : 09AGBPJ9854C1ZB

- Send Email

1.00 / Piece( + 18% GST applicable)

| Business Type | Manufacturer, Supplier |

| Brand Name | MRI- WEBxl |

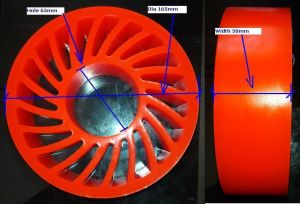

| Material | Synthetic Rubber |

| Shape | Round |

| Click to view more | |

Product Details

Color

Black

Application

Printing

Length

895mm

Printing Type

News paper Printing

Hardness

25-32

Port

UTTAR PRADESH

Delivery Time

3-5 days

Packaging Details

BOX PACKING

Web machine rubber rollers are industrial components, typically with a steel or aluminum core coated in various types of rubber (like nitrile, silicone, or polyurethane), designed for material handling and processing in industries such as printing, packaging, and textiles. These rollers provide essential properties like friction, grip, shock absorption, and controlled hardness to ensure smooth operation and high-quality results by precisely controlling how the "web" or continuous material (paper, plastic, etc.) interacts with the machinery.

Key Characteristics

-

Durometer (Hardness):The hardness of the rubber can be adjusted (e.g., from 25 to 100 Shore A) to achieve the desired level of grip, resilience, and pressure for the specific material and task.

-

Surface Properties:The roller's surface can be even, grooved, or textured to enhance material contact and facilitate specific functions.

Function and Application

-

Material Handling:Web rollers are crucial for guiding and moving a continuous "web" of material, such as paper, plastic, or textiles, through machinery.

-