mahaveerrubber@gmail.com - GST NO. : 09AGBPJ9854C1ZB

- Send Email

1,000.00 - 10,000.00 / piece( + 18% GST applicable)

| Business Type | Manufacturer, Exporter, Supplier |

| Number of Rollers | 1 Roller |

| Machine Capacity | HEAVY LOAD |

| Packaging Type | BOX |

| Click to view more | |

Product Details

Power

Pressure Strenth Rubber

Brand Name

MRI- HeatPress

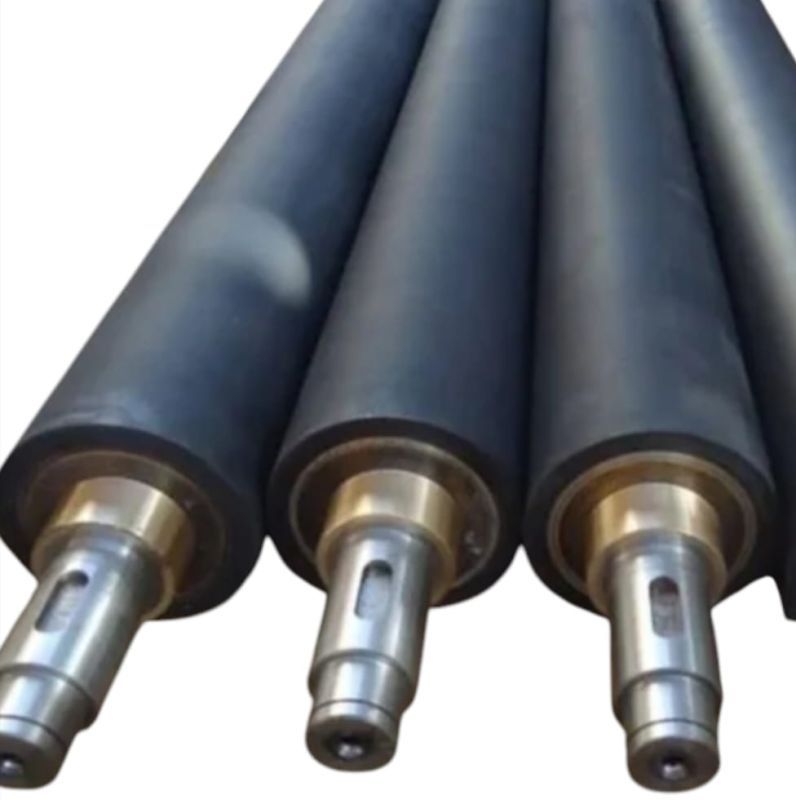

Color

Black

Shape

Round

Finishing

Polished

Material

Silicon Neoprene

Automation Grade

MRI- High Strenth

Port

UTTAR PRADESH

Delivery Time

5-7 Days

Packaging Details

BOX PACKING

We Made Roller from heat-resistant rubber compounds such as silicone, neoprene, or natural rubber, chosen for their ability to withstand high temperatures and pressures.

A thermal lamination rubber roller is a crucial component in thermal lamination machines that applies even pressure and distributes heat to bond a protective film (laminate) to a substrate like paper, preventing bubbles and wrinkles while ensuring a consistent, professional finish. These rollers are made from heat-resistant, durable rubber compounds and can be customized in hardness, size, and surface texture for specific lamination needs.

Key Functions

-

Pressure Application:The roller applies uniform pressure to the laminate film and the material being laminated, which helps to prevent air bubbles and wrinkles from forming in the final product.

-

Heat Distribution:It plays a vital role in distributing heat evenly across the surface during the thermal lamination process, ensuring proper adhesion of the laminate to the material.

-

Durability:Designed to withstand high temperatures and pressures inherent in thermal lamination, these rollers are constructed from high-quality, heat-resistant rubber compounds.

-

Surface Uniformity:The rollers are fabricated to create smooth, even surfaces on the laminated product, contributing to a professional appearance and consistent quality.

Key Features

-

Material:Made from heat-resistant rubber compounds such as silicone, neoprene, or natural rubber, chosen for their ability to withstand high temperatures and pressures.

-

Customization:Can be manufactured with varying hardness levels (durometers), sizes, and surface textures to suit different types of lamination machines and materials.

-

Application:Used in thermal lamination machines to protect documents, photographs, and other printed materials from damage, while also providing a glossy or enhanced finish.

-

Maintenance:Requires regular cleaning to remove adhesive residues to maintain consistent performance and prevent degradation.

Looking for "Rubber Roller Thermal Lamination Machine" ?

piece